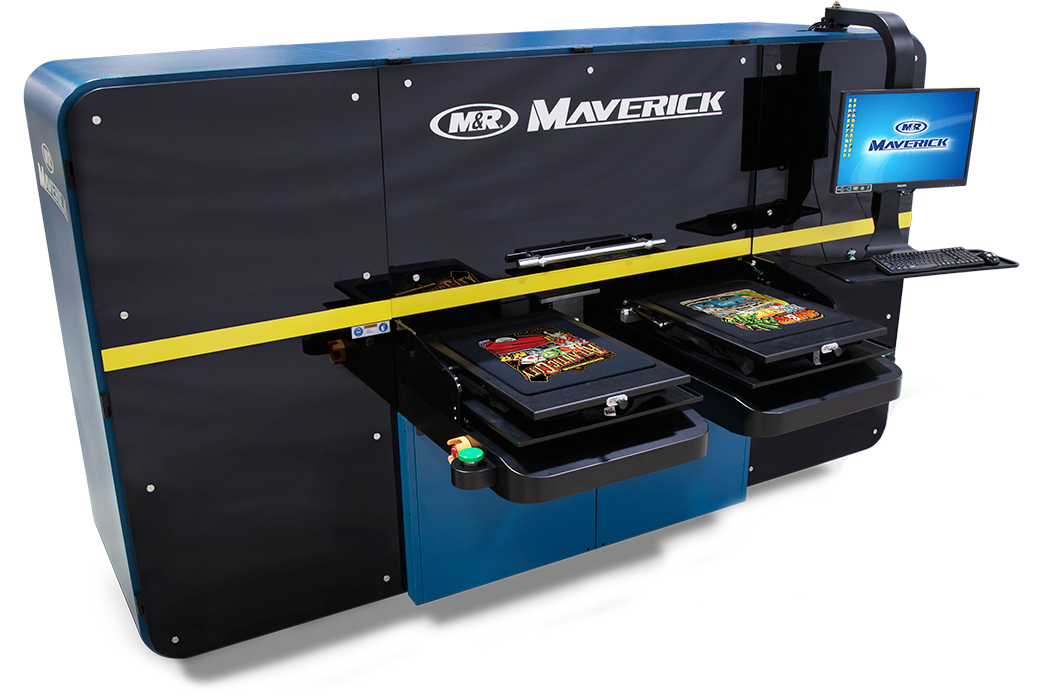

The Maverick™ exemplifies M&R’s commitment to future technologies in the garment decoration process. With an emphasis on print quality and speed, M&R set out to build a leading class, industrial-grade DTG printer.

Featuring a dual-shuttling platform that allows independent pallet shuttling based on the operator’s needs, the Maverick can print images one-off or as multiple copies, and produce them in an array of shirt color combinations. Two digitally controlled heat presses use air cylinders to flatten garment fibers and heat the surface prior to printing.

With fast print speeds, expanded color gamut and rugged construction, the Maverick is designed and manufactured with the same commitment to quality and exacting standards that has made M&R an industry leader for over 30 years.

- • High-speed DTG prints with a 6 color-plus-white expanded color gamut

- • Proprietary RIP software gives complete print parameter control and image costing

- • In-tank agitators and recirculation systems keep inks at peak performance at all times

CONTROL CENTER

- • Machine-mounted control center provides ergonomic controls within reach of the pallet loading area

DESIGN & CONSTRUCTION

- • Heavy-duty, fully-welded steel chassis

- • Industrial bearing rail system and magnetic encoder provide precise carriage movement and trouble-free, long-term operation

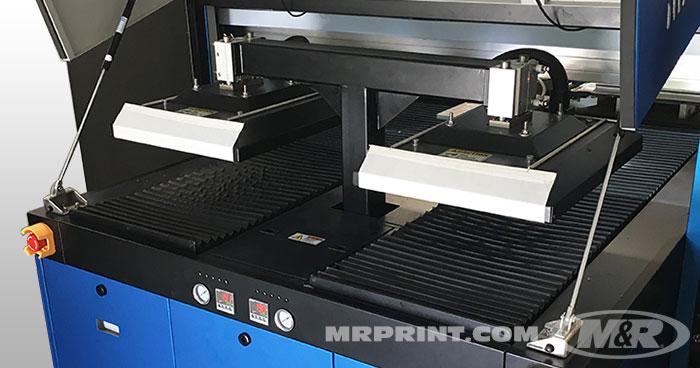

HEATER SYSTEM

- • Quartz heaters on each side of the print carriage further speed up the white ink flash time (Patent Pending)

- • Two on-board, digitally-controlled heat presses not only flatten fibers, but introduce residual heat into the garments to speed up the white ink flash time

INK SYSTEM

- • 5-liter main tanks and two 5-liter white main tanks provide long run times in between refills

- • 6 printheads dedicated to White ink speed up white underbase lay down

- • Complete ink re-circulation system cycles all inks from the main tanks through the printheads and back to ensure optimum performance and consistent print results

- • Expanded color gamut built on Cyan, Magenta, Yellow, Black and additional Red and Green inks

- • The two white ink tanks implement agitators to keep the white ink from settling out, as well as a continuous full system re-circulation

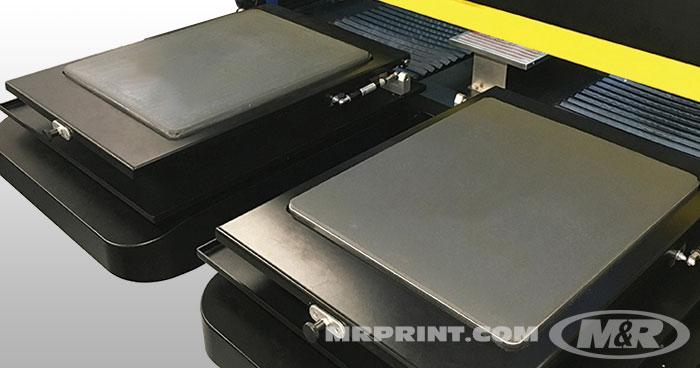

PALLET SYSTEM

- • 40.6 x 50.8 cm (16” x 20”) standard pallets

- • High-speed, dual-shuttling pallets increase productivity

- • Quick-load system with closed-cell rubber pallet covering helps secure garments ensuring the best registration possible, while eliminating the need for spray tack

PRINT SYSTEM

- • 1,280 nozzles (per head) achieve 600 DPI native resolution in single-pass mode and 600 x 1200 DPI in dual-pass mode

- • Printheads are industrial stainless steel construction for excellent durability and extended service life

- • Six color expanded color capacity provides greater color gamut and brilliance while greatly expanding the PMS color matching capabilities

- • Six industrial printheads dedicated to white ink

- • Six industrial printheads support Cyan, Magenta, Yellow, Black, Red and Green

- • Variable drop volume and droplet size improves blends and color gamut

WARRANTY, SERVICE AND SUPPORT

- • M&R 24-hour hotline is staffed 365 days a year

- • One-year limited warranty

- • Parts & supplies available online